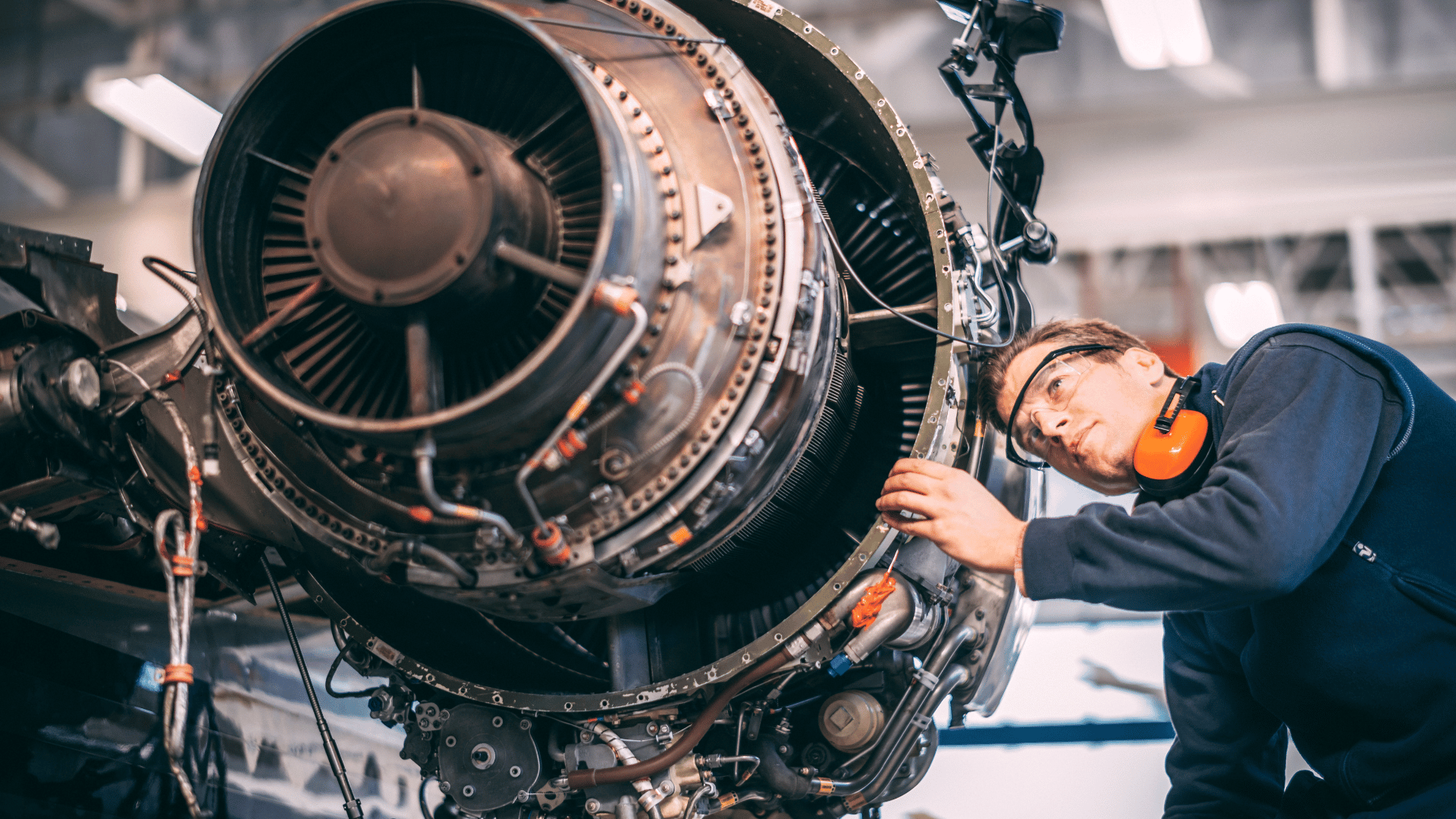

Have you ever looked up at a Boeing 747 in the sky and felt amazed by its size and beauty? Have you ever considered what happens behind the scenes to ensure these airplanes stay safe and fly smoothly? The answer lies in Aircraft Preventive Maintenance. This post will open the aircraft hangar doors, taking you on an exploratory journey into this intricate world. We'll delve into everything from understanding its significance to unpacking various preventive maintenance tasks performed across different aircraft systems. Like ensuring our car gets its regular oil change or tire rotation, airplanes, too, need their share of TLC (Tender Loving Care). Only here, instead of just keeping your vehicle running smoothly, we're talking about preserving hundreds of lives aboard each flight. So buckle up! Let's dive right in! Understanding Preventive Aircraft Maintenance Ensuring the safety of passengers and crew is a top priority in aviation, which is why preventive aircraft maintenance plays an important role. That's where preventive aircraft maintenance comes into play. This process involves regular checks and tasks designed to keep the plane running smoothly and safely. According to the U.S. Department of Energy, preventive maintenance aims to nip potential problems in the bud through routine upkeep and scheduled tasks before they become major issues requiring costly reactive repairs. The Role of Regular Upkeep in Aviation Think of it this way: just as your car needs periodic oil changes, tire rotations, and brake inspections to run optimally over time, similarly, an aircraft also needs consistent care. Maintenance tasks like inspecting spark plugs for wear or checking landing gear tires for proper inflation are vital parts of any comprehensive preventive maintenance program. These steps help avoid unexpected breakdowns and ensure that pilots can rely on their equipment when it matters most - during flight. From Reactive Repairs to Proactive Maintenance In a world where we're so accustomed to fixing things once they break down (reactive repairs), shifting our mindset towards proactive preventive measures might seem unusual. But considering how critical every component is within aviation mechanics — from safety belts to complex assembly operations — it becomes clear why taking early action is necessary. The transition from simply reacting after something goes wrong with your aircraft – thinking significant alterations or fabric patches are needed due to post-damage assessment- to being proactive about preventing those damages before they occur offers multiple benefits, which we will discuss further. As aerospace professionals, we understand that aircraft preventive maintenance isn't just about fixing what's broken - it's about ensuring things don't break in the first place. Aircraft Preventive Maintenance Tasks Additionally, regular inspections and routine maintenance are carried out. This includes looking over engines for wear and tear, ensuring that the navigation systems are up to date, and monitoring overall aircraft health. These consistent checks help spot potential issues early on, allowing for necessary repairs or replacements before a significant problem arises. Key Takeaway Think of preventive aircraft maintenance as your plane's regular health check-up to fly safely. It's all about routine care and early action - inspecting spark plugs, checking tire inflation, updating navigation systems - before minor issues become major problems. Instead of waiting for things to break (reactive repairs), we're making sure they don't in the first place. Types of Preventive Aircraft Maintenance Maintaining an aircraft isn't just about fixing what's broken. It's a continuous process that requires regular inspections and tasks to keep the plane in top shape. This is where preventive maintenance comes into play. Unpacking the Three Types of Inspections In aviation, three main types of checks fall under preventive maintenance. These are 100-Hour Inspection, Progressive Inspection, and Annual Inspection. The 100-hour Inspection is required for all aircraft used for hire. The clock starts ticking when you lift off from your first paid flight. If you're flying privately, though, this doesn't apply unless specified by your manufacturer's instructions or federal aviation administration regulations. If keeping track of hours seems daunting, don't worry. A Progressive inspection system is also designed for frequent operators - such as airlines or charter services. Instead of doing everything at once every hundred hours or annually (for non-commercial flights), it lets them break down the work into smaller parts over time without grounding their fleet too long. Last but not least is our yearly check-up: the Annual inspection applies to all civil aircraft regardless of whether they're used commercially – making sure we're up-to-date with safety belts, landing lights, and more complex assembly operations like checking fuel lines and hose connections. To sum things up: 100-hour inspection: Required for commercial flights; includes comprehensive examination according to federal guidelines, Progressive inspection: Designed for frequent flyers; breaks down large-scale checks into manageable chunks throughout the year, Annual inspection: A must for all civil aircraft; ensures safety and compliance with federal regulations. These preventive maintenance tasks include checks and minor preservation operations like cleaning or lubricating parts. These measures help avoid major repairs or alterations that could ground your plane - and wallet - longer than necessary. Regular preventive maintenance ensures an aircraft's peak performance and safety. Key Takeaway These checks, along with smaller preservation tasks like cleaning or lubricating parts, play a critical role in maintaining the longevity and safety of your aircraft. Regular upkeep helps ensure smooth flights and peace of mind for pilots and passengers. Benefits Derived from Preventive Aircraft Maintenance Preventive aircraft maintenance is more than just a box to check. It's the cornerstone of safe and efficient flight operations. Performing preventive aircraft maintenance correctly can result in considerable safety enhancements, cost reductions, and assurance that regulatory requirements are being met. Safety Improvements Imagine you're cruising at 35,000 feet when suddenly an engine sputters. Not ideal, suitable? That's where preventive maintenance steps in. Regular inspections and upkeep help spot potential issues before they escalate into major problems – ensuring your flights are as smooth as silk. Cost Savings A stitch in time saves nine—this old saying rings true for aviation, too. Tackling minor wear and tear early on helps avoid costly major repairs. Well-maintained planes mean fewer unplanned groundings, which equals happier passengers and better profits. Studies show regular preventive aircraft maintenance leads to longer equipment lifespan, reducing replacement costs. Maintenance Program Compliance: Your Key To The Sky Flying high also means playing by the rules set out by the Federal Aviation Administration (FAA). Staying ahead of mandatory checks ensures your plane doesn't get grounded due to non-compliance – because, let's face it, nobody wants that surprise during their pre-flight checks. The FAA has specific guidelines governing preventive maintenance tasks versus significant alterations or repairs requiring specialized personnel. The Role of Maintenance Management Systems Don't worry; CMMS is here to help you keep track of all your maintenance tasks and ensure records stay up-to-date. Computerized Maintenance Management Systems (CMMS) have got your back. They guarantee that no job is forgotten and records are current. This guide on CMMS can help you understand how they make aircraft preventive maintenance easier. In a Nutshell... To make it clear, regular preventive aircraft maintenance doesn't always cut it. We need more comprehensive strategies. Key Takeaway Preventive aircraft maintenance is a routine task and the foundation of secure, efficient flight operations. Regular check-ups help catch issues early on for smooth flights and cost savings by avoiding major repairs. Staying ahead with mandatory checks ensures FAA compliance - no surprises during pre-flight checks. And don't worry about keeping track; Computerized Maintenance Management Systems (CMMS) are there to give you a hand. Creating an Effective Aircraft Preventive Maintenance Plan When it comes to maintaining aircraft, being proactive is critical. But how do you plan to keep your planes in top-notch condition? Here's where a preventive maintenance program steps into the picture. Crafting the Perfect Maintenance Schedule The backbone of any successful preventive maintenance plan is a well-crafted schedule. It should be thorough enough to cover all necessary tasks but flexible enough to adapt as needs change. To get started, you'll need detailed knowledge about each aircraft component and its ideal lifespan or usage interval before needing attention. These details will guide when different parts like spark plugs or landing gear tires might require service or replacement - thus forming the basis for your maintenance intervals. A critical aspect here is knowing what needs doing and who can perform these tasks. The Federal Aviation Administration has strict rules about who can carry out various types of work on aircraft - some may require a certified mechanic. In contrast, someone with a pilot certificate could handle others. Incorporating Manufacturer's Instructions and Regulatory Requirements Another crucial element in crafting an effective preventive maintenance plan involves incorporating the manufacturer's instructions and regulatory requirements into routine checks. This helps ensure compliance with FAA regulations, which mandate specific checks at regular intervals depending on factors such as hours flown, calendar time elapsed since the last inspection, etc., ensuring safety standards are upheld consistently across all operations. Your preventative program must also accommodate unforeseen issues; despite our best efforts, problems sometimes arise without warning. Having contingencies built into your schedule gives room for significant repairs if needed – without throwing everything else off track. It's no small task, but implementing a comprehensive preventive maintenance program for your aircraft fleet can have big payoffs. Not only does it help avoid costly repairs down the line, but according to the U.S. Department of Energy, such proactive measures can reduce overall maintenance costs by up to 18%. Key Takeaway The preventive maintenance approach ensures that your aircraft stays in peak condition, reducing the risk of unexpected breakdowns. Remember, a well-planned maintenance schedule is not just about following regulations - it's about ensuring safety and reliability for every flight. Complying with Preventive Maintenance Regulations As an aircraft owner or holder of a pilot certificate, it is essential to be familiar with the Federal Aviation Administration's (FAA) regulations. One of the significant areas that the FAA oversees is preventive maintenance. 14 CFR part 43 (appendix A to part 43) defines the guidelines for performing preventative tasks and making alterations on aircraft. This comprehensive guide covers everything from simple fabric patches to complex assembly operations. What's at Stake? The importance of compliance can't be overstated: if your plane doesn't comply with these rules, it cannot fly without special authorization. You don't want your wheels grounded when they should be in the sky. Maintaining spark plug gap clearance and inspecting safety belts and landing lights fall under preventive measures as outlined by FAA regulations. Navigating Compliance Challenges Let's face it: keeping track of numerous inspections, like checking fuel lines or hydraulic connections, might seem overwhelming. But remember – you're not alone. Countless online resources offer practical advice and detailed procedures about adhering to aviation administration standards while regularly checking gear wheel bearings or handling minor preservation operations. Tips For Ensuring Compliance Familiarize yourself thoroughly with FAA regulation Part 143 Appendix A. It's like a treasure map guiding us toward safer skies. Scheduling reminders for tasks such as checking spark plugs and landing gear shock struts can be a game-changer. Consistency is key. Stay updated with any changes in the regulations, because hey - just like flight controls, they're subject to change, too. Preventive maintenance isn't just about avoiding significant repairs or alterations; it's about preserving the safety of everyone aboard your aircraft. So let's strap on our safety belts and ensure we are flying high – not only literally but also regarding regulatory compliance. Key Takeaway Aircraft owners and pilots must understand and comply with FAA preventive maintenance regulations. This includes everything from maintaining spark plug gap clearance to inspecting safety belts. To navigate these rules, get familiar with Part 143 Appendix A, set reminders for routine checks, and stay updated on any changes. Remember - regular preventive maintenance keeps you in the sky and ensures everyone's safety. Role of CMMS in Aircraft Preventive Maintenance Managing preventive maintenance for aircraft can be a complex task. This is where Computerized Maintenance Management Systems (CMMS) come into play, providing valuable help to streamline these processes. Aircraft owners and mechanics need a reliable way to keep track of scheduled tasks like lubrication, inspections, or even minor preservation operations. These are critical not only for the safety of passengers but also because they contribute significantly to extending the lifespan of an aircraft's various systems, such as landing gear tires or flight controls. By offering automated scheduling features, CMMS makes sure no maintenance task slips through the cracks. For example, you wouldn't want your spark plug gap clearance checks forgotten. And who could remember all those fabric patches needed after some wear and tear? The Benefits Go Beyond Streamlining Processes In addition to making life easier when organizing tasks on our maintenance schedule - let's face it: aviation administration isn't precisely easy-peasy lemon squeezy - there's more good news. A well-implemented CMMS allows for better resource allocation by reducing unnecessary labor costs associated with reactive repairs caused by neglected preventive measures. But wait… there's more. Think about this scenario: Imagine getting notified that your landing lights require servicing just before taking off on an important business trip. Wouldn't that be annoying? A proactive approach driven by a smart CMMS would have detected this earlier during routine checks – saving time and money. Maintenance Plan Made Easy With CMMS Building an effective preventive aircraft maintenance plan doesn't have to feel like assembling IKEA furniture without the manual. Using a CMMS, we can automate our schedule according to the manufacturer's instructions and federal aviation guidelines. This means your preventive maintenance program is always in line with best practices for tasks such as checking fuel lines or even more complex assembly operations that require meticulous attention to detail. So there you have it. By streamlining preventive maintenance processes, a good CMMS helps keep our aircraft flying high without hiccups. Who knew software could be so excellent? Key Takeaway Computerized Maintenance Management Systems (CMMS) simplify the intricate task of aircraft preventive maintenance. They ensure all scheduled tasks, and inspections are performed timely and efficiently. This not only enhances safety but also extends an aircraft's lifespan. A CMMS allows for brilliant resource intelligence by reducing costs associated with reactive repairs and enables a proactive approach to resolving maintenance issues before they escalate into major problems. Comprehensive List of Aircraft Preventive Maintenance Tasks Maintaining a bird in the sky isn't just fuel and flight plans. It's also about regular, detailed check-ups to ensure everything is ship-shaped from nose to tail. Let's dive into the specifics. Maintaining the Wings and Fuselage The wings are like your arms; they carry you through life. But unlike your arms, they're subject to incredible stressors that can lead to severe issues if not properly monitored. In aircraft preventive maintenance, checking structural parts for corrosion or damage is crucial, ensuring safety belts aren't frayed or worn out, and examining fabric patches on wings. Here is a comprehensive list of tasks involved in preventive aircraft maintenance, including inspections, lubrication cleaning, and replacements. Fuel Lines & Hydraulic Connections Check-Up Imagine having a top-of-the-line sports car but neglecting its engine oil - pretty soon, you'll have an expensive paperweight. The same principle applies to aviation fuel lines and hydraulic connections. They need regular inspection for leaks or loose hose connections, which could spell disaster mid-flight. Landing Gear Wheel Bearings – Not Just Tires Matter. Your landing gear tires get all the glory when touching down smoothly after a long flight, but spare some thought for those unsung heroes—the wheel bearings—that keep things rolling along without any hitches. An excellent preventive maintenance plan covers everything from routine greasing operations to more complex assembly checks. Last but not least—spark plugs. Think of them as the heart's pacemaker, keeping your engine at the right rhythm. If necessary, regular inspection for spark plug gap clearance and replacement is a crucial part of aircraft preventive maintenance. So there you have it. This isn't an exhaustive list—maintenance tasks can vary depending on your specific bird—but it gives you a good sense of what goes into keeping an aircraft in top-notch condition. Key Takeaway The aircraft is safe and operational. Each task, from examining the wings for signs of wear to routinely greasing wheel bearings, contributes significantly towards maintaining a healthy flight life. This consistent upkeep enhances performance and reduces unexpected downtime due to malfunctions or breakdowns. Ultimately, meticulous preventive maintenance ensures that every journey is as smooth and secure as possible. Conclusion Aircraft Preventive Maintenance is non-negotiable when it comes to the safe flight of an aircraft. You've journeyed through this intricate world, from understanding its significance to learning about maintenance tasks. You discovered that regular upkeep and inspections are crucial for safety. You learned how preventive maintenance moves us from reactive repairs to proactive measures. The benefits? Improved reliability, cost savings, and compliance with Federal Aviation Administration regulations. Crafting a perfect maintenance schedule isn't easy, but it is essential in creating an effective plan. Computerized systems like CMMS streamline these processes while maintaining wings or fuselage forms part of many necessary tasks to keep our steel birds soaring safely above the clouds.

Read MoreCMMS: Streamlining Government Operations for Public Service

Have you ever wondered how the gears of government keep turning or what keeps our public services humming? Well, it's not magic—it's CMMS for Government Operations: Efficiency, Transparency, and Improved Public Service. This behind-the-scenes hero might seem complex at first glance. But think about CMMS as the invisible conductor orchestrating a symphony of work orders and maintenance tasks. In this grand performance of government operations, there are high stakes. The smooth running affects everything from local parks to federal agencies—and that's where we come in! We'll journey together to understand how CMMS improves asset management and enhances transparency within these critical sectors—unveiling insights that could help make your corner of public service more efficient. The Impact of CMMS on Government Operations Imagine a world where government operations run like clockwork, with all assets and resources fully optimized. A CMMS can help government operations reach a new efficiency level by providing automation and data access to critical information related to asset performance and work order management. With CMMS software, we see an enormous leap in efficiency for government operations. A CMMS gives government organizations better control over their maintenance tasks by automating processes and providing easy access to critical data about asset performance and work order management. It ensures unplanned downtime is less likely while budget adherence improves significantly, thanks to its effective resource allocation capabilities. Elevated Efficiency Through Proactive Maintenance Planning In the public sector, having a proactive maintenance strategy matters because this ensures the uptime of essential services citizens depend on daily, from streetlights to water supply systems. When predictive maintenance is paired with real-time data analytics provided by a CMMS, governments can make informed choices and save time, equating to saving taxpayers money. This results in improved service delivery as equipment failures get detected early enough before causing major disruptions - something I bet you've had nightmares about if you're part of those heroic teams keeping our cities running smoothly. Making Transparency A Priority We can't ignore how important transparency is when managing public works efficiently and using taxpayer dollars wisely. Here's where CMMS steps up again – improving transparency within governmental agencies is one of its strongest suits. You might ask: "How so?" Well, a CMMS lets maintenance managers keep track of all service requests, work orders, and inventory spending in real-time. This data-driven decision-making approach allows government organizations to showcase accountability and deliver improved public service - isn't that the dream? Think about it this way: it's like having a detailed roadmap guiding you through your journey instead of wandering, hoping to get where you need to. Boosting Public Service Delivery But the natural beauty isn't just backstage. The effects on everyday people's lives are significant, too. With less downtime, we can respond faster and better to your needs. Key Takeaway Moreover, the power of CMMS software extends beyond mere efficiency. It enhances asset management by predicting maintenance needs and thus prevents costly breakdowns. With such proactive measures in place, it helps governments deliver top-notch public services while keeping a tight rein on budgets. Challenges Faced by Municipalities in Operations Without CMMS Operating without Computerized Maintenance Management System (CMMS) can present numerous hurdles for municipalities. From juggling work orders to tracking assets, manual systems often lead to inefficiencies and mistakes. A key challenge is managing work order management. Keeping track of these tasks can become overwhelming, with an array of service requests coming from various quarters - be it fixing road potholes or maintaining public parks. Traditional paper-based methods are prone to errors, misplacement, and delays that hinder the provision of prompt public services. Maintenance Planning Woes Planning maintenance activities becomes an arduous task without a robust system like CMMS. It's not just about scheduling regular upkeep; it also involves anticipating potential equipment failures and coordinating preventive measures proactively. Manual processes fail to provide this foresight, leading to more reactive than proactive maintenance. In addition, there's no easy way for technicians on the ground level to communicate with higher-ups regarding progress updates or additional resource needs, which creates unnecessary bottlenecks in operations. The Struggle with Asset Management Asset management also poses challenges for municipalities operating sans CMMS software. Failing at asset inventory means being oblivious about the location or condition of valuable resources, which eventually results in lost assets over time—leading to fiscal losses and operational disruptions due to unavailability when needed the most. Without an effective system for monitoring asset performance, making informed decisions is difficult. As a result, resources are often allocated based on guesses rather than actual need or value generated by each asset—hindering the optimization of public funds usage. Resource Allocation Problems A final challenge is resource allocation. Decision-making becomes haphazard at best without real-time visibility into ongoing maintenance tasks and assets' status provided by CMMS software—this lack of clarity results in inefficient distribution of manpower and equipment that could be better utilized elsewhere. Concluding, there's much more to cover. But these challenges are just the beginning when dealing with municipal operations without a CMMS—it's only scratching the surface. Key Takeaway Without a CMMS, municipalities struggle with inefficient work order management, daunting maintenance planning, complex asset management, and haphazard resource allocation. Manual methods can lead to errors and delays in public services. The lack of real-time visibility into operations often results in poor decision-making and ineffective use of resources. Why Municipalities Are Shifting From Spreadsheets to CMMS Municipalities have started noticing the limitations of traditional spreadsheets for managing their vast array of assets and maintenance tasks. The static nature of spreadsheets can lead to information silos, inefficient resource allocation, and poor visibility into asset performance. A CMMS can be employed to aid municipalities in addressing their asset and maintenance task management challenges. By adopting advanced solutions like CMMS software, cities can optimize their work order management processes while enhancing transparency in government operations. Enhanced Asset Visibility and Performance with CMMS A significant advantage that CMMS offers over spreadsheets is enhanced asset visibility. It allows municipalities to accurately track all assets' performance across various public works projects. In addition, leveraging data-driven decision-making offered by these systems makes it easier than ever for municipal teams to spot equipment failures early on. This leads not only to improved service request handling but also boosts overall productivity through reduced downtime. Streamlined Inventory Management and Reduced Downtime with CMMS The shift from using conventional methods towards more efficient tools such as a robust CMMS platform has significantly allowed cities and towns around the country to streamline inventory management practices within their departments. They no longer need to spend valuable time updating multiple records manually or wrestling with outdated systems when there's easy access to real-time data at their fingertips via cloud-based applications provided by most modern-day software providers. Here's how one municipality did it: An organized digital record replaced chaotic paper trails, allowing quick reference during audits or inspections, Daily maintenance tasks were streamlined, leading to more efficient resource management, Automated notifications reduced equipment downtime and increased uptime, contributing positively to the local economy. This shift is not just about making life easier for government maintenance professionals. It's also about creating a healthy living environment for citizens by ensuring that public services run smoothly with quicker response times, ultimately improving general satisfaction. Let's talk about the ability. It plays a vital role in everything we do, right? But sometimes, it can be challenging to understand this concept fully. No need to worry, for we are here to assist. Key Takeaway Government agencies are ditching spreadsheets for CMMS to manage assets and maintenance tasks. This switch enhances visibility, optimizes work order processes, and improves transparency. With real-time data access through cloud-based applications, municipalities streamline inventory management and reduce downtime - making public services more efficient while boosting citizen satisfaction. The Advantages of Using a CMMS in Government and Public Service Regarding government operations, the efficiency of work orders can make or break public service quality. One proven invaluable tool is the Computerized Maintenance Management System (CMMS). Let's take a look at why. Efficient Management of Work Orders with CMMS A key benefit of using CMMS software lies in its ability to streamline work order management. Gone are the days when maintenance teams struggled with piles of paper-based requests, which often led to miscommunication and delays. With digital work orders, everything gets simpler. Not only does this let government agencies track maintenance tasks effectively, but it also provides complete visibility for government maintenance professionals into the status of each request - making life much easier for everyone involved. The data-driven decision-making enabled by such systems also ensures faster response times to service requests. For instance, predictive maintenance helps identify potential equipment failures before they happen, reducing downtime considerably. Effective Preventive Maintenance Strategies with CMMS In addition to handling daily operational needs like managing inventory spending or facilitating quicker responses, an efficient CMMS system brings another critical advantage: effective preventive maintenance strategies. This is crucial because well-maintained assets significantly enhance performance – whether we're talking about infrastructure elements like roads and bridges or office facilities used by federal organizations. It means fewer unplanned downtimes, which contribute directly towards improving economic stability and ensuring uptime for essential services. "Prevention," says one seasoned professional," is always better than cure." Predicting problems before they occur reduces maintenance costs and helps extend the life of assets. This is crucial in the public sector, where resource allocation and budget management are scrutinized. In short, CMMS for government operations offers various benefits that lead to increased efficiency, transparency, and improved public service. From work order management and preventive maintenance to inventory control - all these elements play a vital role in ensuring our governments run smoothly. Key Takeaway Using a CMMS boosts government operations by simplifying work order management and enabling proactive maintenance strategies. This not only increases efficiency but also improves transparency in task tracking. By predicting potential issues, the system reduces downtime and extends asset life - which is crucial for better public service and responsible budgeting. The Importance of CMMS Software for Government Maintenance Computerized Maintenance Management System (CMMS) software plays a pivotal role in helping improve government maintenance. It is the backbone, enhancing efficiency and contributing to economic stability by minimizing unplanned downtime. Role of Proactive Maintenance in Reducing Unplanned Downtime A CMMS allows for proactive maintenance, which is crucial in preventing equipment failures that can lead to service disruptions. We avoid surprises and ensure uninterrupted public services by scheduling regular checks and maintaining up-to-date asset inventory. Maintenance professionals within the government sector are empowered with quick access to critical data such as work orders or information about impending equipment downtimes. With EMS Software, these professionals can swiftly generate reports on service requests and asset downtime. This immediate access aids faster response times when dealing with issues related to machinery or infrastructure. Essentially, it's akin to having a superpower - being able to predict problems before they occur. Using a CMMS ensures uptime and enhances resource management through the intelligent allocation of manpower based on task priority levels defined within the system. The beauty of this software isn't just its predictive capabilities, though. It also supports preventive maintenance strategies that help maintain assets at their optimal performance level while prolonging their lifespan – something all tax-paying citizens would be thrilled about because it means better use of resources. Boosting Economic Stability Through Efficient Resource Allocation Economic stability depends mainly on efficiently utilizing resources — human, financial, and material — everything counts. Here's where our hero steps into play again: A well-implemented CMMS improves resource allocation by helping prioritize tasks based on urgency or importance, thereby saving time and costs. But the wonders don't cease here. The data-driven decision-making enabled by a CMMS can significantly reduce maintenance costs. For instance, it allows for streamlined inventory management so you don't hoard unnecessary parts or run out of crucial ones when needed. Not only does this tool boost government transparency, but it also achieves this by offering resources and tools to the public. It's a game-changer. Key Takeaway CMMS software is the unsung hero in government maintenance, enhancing efficiency and contributing to economic stability. Its superpower lies in its predictive capabilities, allowing for proactive maintenance that prevents unplanned downtime and ensures optimal resource use. CMMS is not just a cost-saver but also boosts transparency by providing public access to crucial data. How a CMMS Enhances Efficiency and Transparency in Government Operations A Computerized Maintenance Management System (CMMS) is a critical tool that improves government efficiency, transparency, and service delivery within government operations. Let's take the case of work order management. Without an effective system like CMMS, handling numerous service requests can be challenging for maintenance professionals in the public sector. However, with MicroMain's user-friendly platform, tracking maintenance tasks, allocating resources accurately, and improving response times for each work order placed by citizens or internal departments becomes easier. This enhanced efficiency in government operations ultimately contributes to improving government services. Maintenance Planning Enhanced by Real-Time Data Data-driven decision-making plays a significant role when planning preventive maintenance tasks to avoid equipment failures within governmental agencies. A study shows that a robust CMMS enables government organizations to access real-time data through summary charts and graphs, improving their decision-making processes. This helps reduce unplanned downtime, which could disrupt essential services these entities provide, contributing significantly towards economic stability and ensuring the uptime of assets vital for daily operations. The Role of Resource Allocation in Streamlining Inventory Spending Budget adherence is crucial for organizations, especially those operating under tight budget constraints like federal organizations. The ability to streamline inventory spending via efficient resource allocation strategies comes into play here - this is where using CMMS shines. When integrated with advanced management software like MicroMain's solution, Supplier Diversity initiatives help ensure every dollar spent is tracked and accounted for, further enhancing asset performance. Proactive Maintenance Reduces Downtime A CMMS system doesn't just help manage maintenance. It also enables government organizations to predict potential issues before they occur, allowing them to switch from reactive to proactive approaches. This shift towards predictive maintenance can drastically reduce downtime of critical assets, ensuring smoother operations. Predictive maintenance not only boosts public service but also frees up resources and time that can be put toward other urgent matters within the organization. Key Takeaway Adopting a CMMS boosts efficiency and transparency in government operations and enhances asset performance and service delivery. This tool significantly improves government by making tracking tasks easier, optimizing resource allocation, providing real-time data for decision-making, and enabling proactive maintenance strategies. It ensures smoother daily operations and an overall better public service. Conclusion Adopting computerized maintenance management software boosts efficiency and transparency in government operations and enhances service delivery, asset performance, and managing maintenance. This tool significantly improves government by making tracking tasks easier, optimizing resource allocation, providing real-time data for decision-making, and enabling proactive maintenance strategies. It ensures smoother daily operations and an overall better public service.

Read MoreMaximizing Facility Management Efficiency with CMMS Software

Ever wonder how a city runs smoothly? It's like an orchestra, every instrument playing its part perfectly. Imagine being the conductor of this symphony - that's what it feels like to be in facility management. But here's where it gets tricky: How do you keep track of everything and ensure nothing falls through the cracks? This is where our secret weapon comes into play - CMMS software. Picture yourself at the helm with a powerful tool capable of turning chaos into harmony. "But wait!" I hear you say, "What on earth is CMMS?" software is a real lifesaver. CMMS allows you to remain up-to-date on your assignments and provides an understanding of the condition of your possessions. With CMMS, not only can you manage day-to-day operations efficiently, but also predict potential issues before they turn into costly repairs. Understanding Facility Management and its Relevance The business world today needs more than just a well-structured plan to thrive. Creating an atmosphere that boosts efficiency, comfortability, security, and sustainability is essential in the present business world. This is where facility management (FM) comes into play. ISO 41011, the international standard for FM, defines it as an organizational function that integrates people, places, and processes within the built environment to improve the quality of life of people and enhance organizational effectiveness. The Diverse Roles of Facility Managers A key player in this setup is a facility manager. With diverse roles ranging from building operations to project management - they ensure that every part fits perfectly in your company's jigsaw puzzle. Imagine being at work without worrying about mundane things like faulty ACs or inadequate lighting – seems ideal, right? That's what good facility managers do. They create conducive environments so employees can focus on their core tasks rather than dealing with minor disruptions. They handle everything from return-to-work processes after emergencies to long-term sustainability planning. Not only do they take care of emergency responses, but they also have strategic responsibilities such as business continuity planning and ensuring smooth operations no matter what curveballs are thrown their way. Beyond handling daily issues, these professionals strategize around future space needs while balancing costs & employee satisfaction—essentially making sure everyone gets what they need when they need it without breaking the bank. The bottom line? A great facilities manager equals happy employees, which translates into higher efficiency and productivity for your organization. The Role of CMMS Software in Facility Management Computerized Maintenance Management System (CMMS) software is an indispensable tool for modern facility management. Its primary function is streamlining maintenance operations, turning a potentially chaotic process into a well-oiled machine. The Functionality of CMMS Software A robust CMMS solution offers more than just tracking and editing capabilities. The engine drives preventive and predictive maintenance strategies by generating work orders, creating reports, and delivering actionable insights from data analytics. This innovative technology helps facilities manage their assets better by providing a centralized system to track all aspects of maintenance scheduling - think tasks as simple as replacing light bulbs to more complex jobs like HVAC system overhauls. No matter the size of the company or type of built environment you're managing, effective use of this software can significantly improve operational efficiency while reducing downtime - two factors directly linked to improved customer satisfaction levels. Many facility managers rely on CMMS software solutions because they make it easier to keep tabs on labor hours spent per task or project. Analyzing these metrics regularly using built-in tools within the platform itself allows them to fine-tune processes, which ultimately leads to lower labor costs without sacrificing service quality. Making Sense Out Of Chaos With Work Order Management To further understand how crucial CMMS systems are for smooth operation, let's consider work order management – one aspect where benefits shine brightly. Imagine your organization getting bombarded with hundreds, even thousands, requests each day – be it repair requirements, new installations, scheduled check-ups, etc., trying to handle this volume would seem like herding cats. But with reliable computerized maintenance management solutions, every request gets logged systematically and assigned to appropriate maintenance teams. It's an organized, efficient method that not only keeps operations running smoothly but also minimizes the risk of tasks being overlooked. When you start exploring how to get the most from your CMMS, remember it's all about optimization – whether we're talking time, resources, or efforts. This way, facilities can maintain their assets better while ensuring top-notch service quality, thereby improving the overall business operations. Key Takeaway: With CMMS software, facility management becomes a breeze. It turns maintenance operations into streamlined processes by driving preventive and predictive strategies. This software also manages work orders efficiently, generates comprehensive reports, and provides valuable insights through data analytics. The result? Improved operational efficiency and reduced downtime - which means happier customers. Plus, it's a crucial tool when dealing with large volumes of work orders. Benefits of Using CMMS Software in Facility Management In the dynamic world of facility management, using a Computerized Maintenance Management System (CMMS) is like having an ace up your sleeve. This powerful tool doesn't just make work more manageable; it transforms how you manage maintenance operations. Cost-Effective Solutions with CMMS A significant benefit that stands out when discussing CMMS software solutions is cost-effectiveness. Picture this: equipment failure strikes unexpectedly, and repair costs skyrocket because spare parts are unavailable or obsolete. Sounds stressful? Well, here's where CMMS shines. The system not only alerts you about impending equipment failures but also keeps track of inventory levels for critical spare parts - all. At the same time, ensuring predictive maintenance tasks are scheduled to reduce downtime. These capabilities save precious labor hours and prevent unnecessary expenditure on emergency repairs. This ability to streamline processes directly impacts your bottom line by reducing overall operational expenses. You may ask yourself, "Can any size company use a CMMS?" The answer is a resounding yes. Whether you're managing facilities for a small business or overseeing asset management at the enterprise level, no doubt implementing these systems can offer substantial benefits. Maintenance Scheduling Made Easy Beyond cost savings, another advantage lies in preventive maintenance scheduling, which can extend asset life significantly – now, isn't that something we'd all want? Think less reactive firefighting and more proactive planning – ensuring assets run smoothly before issues become expensive problems. Through streamlined work order management and automated service request processing abilities provided by most software solution providers today, you can be sure of improved maintenance team productivity and customer satisfaction. Remember, the key to successful CMMS implementation lies in thorough training for both facility managers and maintenance workers. With proper usage, a CMMS becomes an invaluable tool that not only enhances your management process but also makes work orders seem like less of a chore. Key Takeaway: Picture the power of CMMS software transforming your facility management. Not only does it make tasks more manageable, but it also brings cost-effective solutions by preventing unexpected equipment failures and reducing operational expenses. It's a tool that any size company can use for improved maintenance scheduling, extending asset life significantly, and boosting team productivity and customer satisfaction. Choosing the Right CMMS Software for Efficient Facility Management Picking the perfect CMMS software solution can feel like searching for a needle in a haystack. But it's crucial to find one that aligns with your facility management needs. Factors to Consider When Choosing a CMMS The market today is flooded with options. So, how do you narrow down your choices? Let's start by looking at what you need from maintenance management software. Your top priority should be creating reports that help analyze data and make informed decisions about asset work and routine maintenance scheduling. Surprisingly, many companies miss out on this benefit of their CMMS software. You also want something user-friendly that simplifies keeping track of daily tasks such as service requests or tracking spare parts inventory levels - features that not every product offers but are essential to manage maintenance operations effectively. Last, don't overlook customer satisfaction when considering potential vendors. This might seem unrelated at first glance, but remember: happy customers often mean high-quality products. You wouldn't buy any other product without checking reviews first; why should your choice of enterprise asset management system be any different? Nailing Down Your Needs Beyond these primary considerations, there are more specific aspects related to individual business requirements – after all, no two facilities operate identically. It's, therefore, vital to choose an EAM software explicitly suited for the size of the company you have or even tailor-made solutions if necessary. This involves understanding what it means to say 'maintenance management process.' For instance, does yours affect more preventive than reactive repair? Do specific equipment downtime periods cause significant disruptions? What labor hours are involved in your maintenance scheduling? Questioning these matters can assist you in selecting the most suitable option. Remember, the goal isn't to get lost in a sea of software solutions but rather to use CMMS as an aid that simplifies and streamlines processes while keeping assets running smoothly. Consider The Future think about where you see your business's facility management heading. Will there be growth or changes that could influence which system is ideal? Considering the future implications of facility management, it is essential to plan for potential growth and changes that could affect which method is most suitable. Key Takeaway: Choosing the perfect CMMS software for your facility management is like finding a needle in a haystack. Start by identifying what you need - user-friendly features, detailed reports, and positive customer reviews are vital considerations. But don't stop there; think about specific business needs and future growth plans. Remember, it's not just about picking any solution but one that simplifies tasks, meets your unique requirements, and has room to accommodate your goals as you expand. How CMMS Software Helps Facility Managers A CMMS is an invaluable tool for facility managers, enabling them to efficiently manage service requests, track assets, and optimize maintenance operations in real-time. With the proper setup, it lets you manage service requests, track assets, and streamline maintenance operations in real-time. The U.S. Bureau of Labor Statistics states that properly implementing a CMMS involves getting everyone on board, building an extensive database, and providing adequate training. These steps are crucial to unlock its full potential. Streamlining Service Requests The daily life of a facility manager is filled with numerous tasks requiring immediate attention. From maintaining asset life to handling work orders - it's like juggling fireballs. But here's where CMMS software comes into play. A good quality CMMS solution, like MicroMain, for instance, allows you to efficiently handle all service requests by digitizing them onto one platform. This saves time spent on paperwork while also ensuring no request slips through the cracks. Easing Asset Management Another critical role played by any decent CMMS is in asset management: keeping track of equipment downtime and inventory levels becomes much easier when digitally recorded within your software system. This simplifies preventive maintenance scheduling, which ultimately reduces costs associated with labor hours and spare parts usage. Plus, as per studies conducted by leading market analysts today - companies using these tools experience significant improvements in their overall customer satisfaction scores, too. Maintenance Scheduling Made Simple Schedule work or routine repair history tracking could sometimes get overwhelming without an organized approach but fear not. A well-implemented CMMS helps automate this process entirely - thus freeing up time for facility managers to focus more on strategic initiatives that matter. So, if you're looking to reduce downtime and increase efficiency in your built environment, it's worth giving CMMS serious consideration. Remember - it's not just about the software itself; it's how well you use it. Key Takeaway: CMMS software can revolutionize your facility management. It digitizes service requests, streamlines maintenance operations, and eases asset tracking in real-time. To get the most out of it, you need a well-built database and proper training for everyone involved. The correct implementation will save time on paperwork and reduce downtime and costs associated with labor hours or spare parts usage while enhancing overall efficiency. Maximizing Facility Management with CMMS Software Regarding facility management, CMMS software solutions have proven their worth. But how can we squeeze out more benefits from these tools? The answer lies in training and informed decision-making. The Role of Training in Maximizing Benefits from a CMMS IFMA Programs and Services, for instance, provide comprehensive resources on getting the most out of your CMMS solution. It's no secret that proper setup and utilization of a well-chosen CMS system can significantly improve business operations. This isn't just an assumption; data backs this up. Ensuring everyone comprehends the CMS is essential. When members know how to generate work orders or analyze maintenance scheduling data, they become more efficient at managing daily tasks. This isn't limited to maintenance teams but extends even further to include other stakeholders like asset managers, who are often tasked with ensuring assets' longevity by minimizing equipment downtime through preventive maintenance measures made possible by accurate repair history tracking using CMMS software solutions. To make things easier for all involved parties - including service request submitters (typically customers) whose satisfaction is directly tied into smooth-running processes - modern-day enterprise asset management systems integrate seamless customer-facing interfaces, allowing users to lodge issues quickly while providing them updates about resolution progress in real-time. However, adopting new technology always brings challenges along – mainly related to people's resistance towards change due to its perceived complexity, causing anxiety among workers, which then hinders successful implementation, leading organizations to miss potential benefits they could achieve if appropriately implemented. This leads us back full circle: Training doesn't simply mean learning tool's functions but rather understanding its value across organizations, starting a top-down approach where leaders must take the initiative to set the right tone regarding the importance technology plays today's business landscape, thereby fostering positive attitudes towards adoption among employees. So, before we dive into any advanced features of your CMMS or EAM software solution, let's get the basics right first - because that's where actual maximization starts. Key Takeaway: Getting the most out of your CMMS software isn't just about using it but understanding its value and integrating it into daily operations. Comprehensive training helps ensure everyone knows how to use the system efficiently. Plus, adopting a top-down approach encourages positive attitudes toward tech adoption among employees. Future Trends in Facility Management and CMMS Software The landscape of facility management is ever-evolving, with technological advancements continually reshaping the sector. One tool that's proving instrumental in this evolution is Computerized Maintenance Management System (CMMS) software. The Role of AI and IoT in the Future of CMMS AI (Artificial Intelligence) and IoT (Internet of Things), two emerging technologies, are essential for the advancement of CMMS (Computerized Maintenance Management System) software, as well as providing enhanced efficiency, predictive power, and automation in facilities management. They offer the potential for even more efficiency, predictive power, and automation within facilities management. AI can now swiftly assess an abundance of data, more so than ever before. This ability could enable quicker decision-making processes regarding maintenance tasks - leading to reduced equipment downtime, improved preventive maintenance scheduling, and better asset life expectancy calculation - ultimately increasing overall productivity. IoT devices can communicate directly with a CMMS system via sensors installed on assets or equipment. These smart devices provide real-time updates about an asset's condition, allowing facility managers to monitor everything from temperature changes to vibrations – detecting issues before they become costly problems. Such integration helps streamline work order management by automatically generating service requests when anomalies are detected. This proactive approach not only increases customer satisfaction but also enhances operational efficiency by reducing labor hours spent manually inspecting each piece of equipment. Apart from boosting daily operations' effectiveness at a micro level, these trends also contribute to shaping strategic decisions at a macro level. With increased visibility into assets' performance through robust reporting features provided by advanced Enterprise Asset Management (EAM) software, facility managers can make more informed decisions about asset management and replacement strategies. While we are only at the tip of the iceberg regarding what AI and IoT integration with CMMS software could achieve, it's clear that these future trends can revolutionize how facility maintenance is conducted. As technology continues to evolve, so will our methods for maintaining assets – leading us into an exciting new era in facility management. Key Takeaway: As we step into an exciting new era of facility management, AI and IoT are taking center stage in CMMS software. This potent tech duo allows for faster data analysis, quicker decision-making, improved maintenance predictions, and increased task automation. The end game? Minimizing equipment downtime and labor hours while maximizing productivity and customer satisfaction with the assistance of this innovative maintenance software. On top of that, these advancements are actively shaping the future landscape of strategic asset management. Conclusion It's a fact: CMMS facility software is revolutionizing how maintenance managers and facility professionals approach facility maintenance and address maintenance issues. With this CMMS facility software, managing assets, scheduling maintenance tasks, and keeping track of work orders becomes effortless. This powerful tool not only streamlines operations but also predicts potential maintenance issues before they morph into expensive repairs, helping reduce costs. You've learned how it enhances customer satisfaction by ensuring efficient service request handling and boosts your bottom line by reducing equipment downtime. The power to maximize facility management with CMMS facility software is in your hands - use it wisely to simplify maintenance. Remember, selecting the right solution for your business needs is crucial; thorough training ensures you extract maximum benefits from your chosen system. Stay ahead of trends like AI integration in CMMS as technology evolves. Keep innovating because successful facility management isn't about maintaining the status quo—it's about improving daily!

Read MoreThe Crucial Role of CMMS in Property Management