Have you ever found yourself weighed down by the costs of unplanned downtime and unexpected equipment failures in your manufacturing operations? If so, then understanding preventive maintenance asset management may be your business's lifeline.

At MicroMain, maintaining your assets' efficiency, reliability, and longevity is a crucial part of business success. This starts with a strategy - a preventive one. Preventive maintenance asset management is a practical and strategic approach to managing, optimizing, and maintaining your organization's assets effectively and efficiently throughout its entire lifecycle. Simply put, it's about taking care of your assets before they break, ensuring they perform at their peak, and allowing your business to avoid massive costs from sudden breakdowns and delays.

We recognize that navigating the intricacies of preventive maintenance may initially appear overwhelming. It's easy to get lost in testing, servicing, calibration, inspection, adjustment, alignment, and installation. However, this guide will break down everything you need to know about preventive maintenance asset management, from its basic concept to its application, technology adoption, benefits, planning, and case studies in simple language, adhering to our easy-to-understand approach.

Before we delve into the nitty-gritty, let's highlight the critical facets of preventive maintenance asset management:

- Proactivity: Regular action is taken to maintain the conditions of assets and prevent potential problems.

- Strategy: It's systematic and planned, employing data and technology to make informed decisions.

- Efficiency: The goal is to boost performance, reduce downtimes, optimize resource use, and extend asset lives.

- Cost Management: By preventing unplanned breakdowns, unnecessary maintenance costs are avoided.

Let's break this down further with a visual representation:

Welcome to the comprehensive guide to understanding preventive maintenance asset management. Read on to equip yourself with the knowledge and tools needed to enhance your business's overall efficiency and success.

Understanding the Concept of Preventive Maintenance

What is PM in Maintenance?

Preventive maintenance is the proactive approach to maintaining assets to reduce the risk of equipment failure and business interruptions. It involves regular maintenance tasks, including cleaning, lubrication, inspection, and parts replacements, to ensure the best operating conditions and the most extended equipment life. This approach allows businesses to focus on maintaining their assets proactively rather than reactively.

At MicroMain, preventive maintenance is crucial for organizations that value safety, time, and money. By relying on preventive maintenance, you can ensure that your assets are at their most reliable and longest-lasting, optimizing your organization's asset management practices.

The Importance of Preventive Maintenance in Asset Management

Preventive maintenance lays the foundation for successful asset management. It ensures that equipment and systems operate efficiently and safely, thereby contributing to a high level of safety for your employees. Furthermore, it helps you avoid costly repairs in the future, thus saving you time and money.

A properly functioning preventive maintenance program also ensures that operational interruptions are minimal. In other words, preventive maintenance is critical in maintaining business continuity, and that's why we at MicroMain emphasize its importance in asset management.

The Four Major Types of Preventive Maintenance: Usage-based, Calendar/Time-based, Predictive, and Prescriptive

- Usage-based Maintenance: This form of preventive maintenance is triggered by the actual use of a system. It considers the average daily use or environmental impact of a piece of equipment and uses this data to forecast future inspections or maintenance deadlines. An example of this would be getting your tires rotated every 5,000 miles.

- Calendar/Time-based Maintenance: Time-based maintenance is when work orders are set to fire automatically according to a calendar interval. This type of maintenance is beneficial for equipment that needs to be serviced based on a calendar schedule, regardless of usage or performance.

- Predictive Maintenance: This proactive maintenance strategy monitors the actual condition of an asset to determine what maintenance tasks need to be done. It is not time-based but trigger-based, requiring advanced technologies such as machine learning and predictive analytics.

- Prescriptive Maintenance: This type of maintenance takes predictive maintenance further by providing actionable insights and recommendations on the most effective maintenance actions. It considers asset criticality, cost, and operational priorities to optimize maintenance decisions.

At MicroMain, we understand the nuances of these different types of preventive maintenance and offer solutions that cater to all of them. We aim to empower organizations to implement the most appropriate preventive maintenance strategies for their needs, ultimately improving efficiency and reducing downtime.

In the following sections, we will delve deeper into the role of technology in preventive maintenance, the benefits of implementing such strategies, and how to develop a preventive maintenance plan. Stay tuned to learn more about preventive maintenance asset management.

The Role of Technology in Preventive Maintenance

In an era where technology drives most industries, the role of technology in preventive maintenance is pivotal. It helps reduce costs, enhance efficiency, and improve the longevity of assets.

The Impact of Machine Learning and Predictive Analytics in Preventive Maintenance

Machine Learning (ML) and Predictive Analytics have revolutionized preventive maintenance. These technologies analyze historical data and identify patterns that might be missed by human observation. They accurately predict equipment failure, helping schedule timely maintenance activities and avoiding unnecessary downtime. At MicroMain, we leverage these advancements to deliver the most value to our customers, helping them achieve their maintenance goals.

The Role of IoT in Enabling Predictive Maintenance

The Internet of Things (IoT) is crucial in enabling predictive maintenance. IoT devices collect real-time data from assets, providing invaluable insights into their condition. This constant data stream feeds into predictive maintenance models, allowing them to make precise predictions about when maintenance is needed. IBM points out that IoT has allowed predictive maintenance models to flourish as they receive the data they need to make crucial maintenance predictions.

How AI and IoT Reduce Resources Allocated to Preventive Maintenance Tasks

Artificial Intelligence (AI) and IoT technologies have optimized both assets and activities in the industrial sector. They have resulted in a significant reduction in the resources allocated to preventive maintenance tasks. More extensive data collection and analysis have enabled manufacturers to improve the reliability of their operations and products. AI and IoT solutions allow asset operators to truly understand the quality of the assets they are deploying, driving new asset lifecycle strategies that reduce downtime and costs.

The Use of CMMS and EAM in Streamlining Preventive Maintenance Tasks

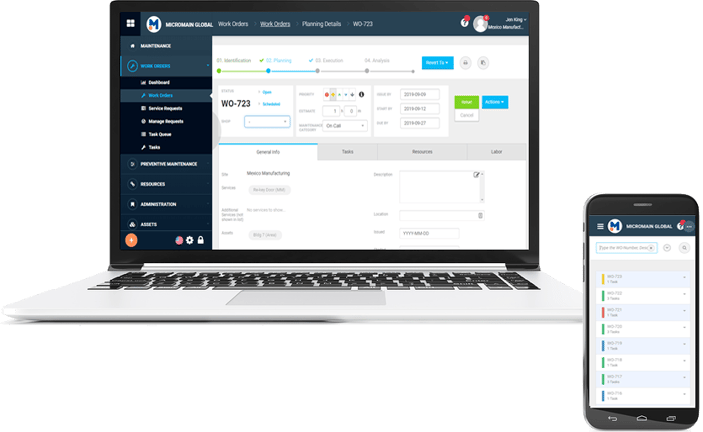

Using Computerized Maintenance Management Systems (CMMS) and Enterprise Asset Management (EAM) tools is integral in streamlining preventive maintenance tasks. These software solutions, like the ones we offer at MicroMain, automate work requests, standardize processes, and increase resource visibility, making the preventive maintenance process more efficient and effective. They also extend the reach of predictive maintenance by allowing technicians, engineers, and operators to track and respond to critical maintenance issues from anywhere.

In conclusion, the role of technology in preventive maintenance is immense. By harnessing the power of ML, predictive analytics, IoT, AI, CMMS, and EAM, businesses can effectively implement preventive maintenance asset management strategies, leading to significant cost savings, enhanced efficiency, and improved asset longevity.

The Benefits of Implementing Preventive Maintenance

Transitioning from reactive to preventive maintenance asset management can bring numerous benefits to your organization. Let's explore the most significant advantages.

Cost Savings and Improved Organization

Preventive maintenance can lead to substantial cost savings for your business. Regular inspections and maintenance can detect potential issues early on, allowing you to address them before they escalate into major problems. By implementing a preventive maintenance strategy, you can avoid costly repairs or replacements, thus optimizing your maintenance budget and asset utilization.

Moreover, preventive maintenance can lead to improved organization within your business. Since preventive maintenance is scheduled and planned, it's easier to manage. You can automate these tasks by utilizing a Computerized Maintenance Management System (CMMS) like the one we offer at MicroMain, freeing up valuable resources. This lets your team focus on more critical tasks, increasing productivity and efficiency.

Ensuring Always-On Operations and Business Continuity

Unexpected equipment failure can lead to disruptions in your operations. However, with preventive maintenance, you can minimize the likelihood of such unexpected breakdowns. Ensuring your equipment is always in optimal working condition allows your operations to run smoothly without unplanned disruptions. This helps in guaranteeing always-on operations and business continuity.

Increased Asset Reliability and Operational Uptime

One of the key benefits of preventive maintenance is increased asset reliability. Regular maintenance not only prolongs the lifespan of your assets but also improves their performance. This results in fewer equipment failures and increased operational uptime. With preventive maintenance, you can optimize asset performance, increase asset lifespan, and minimize repair costs.

In conclusion, implementing preventive maintenance strategies can bring numerous benefits to your organization, including cost savings, improved organization, always-on operations, and increased asset reliability. At MicroMain, we're committed to helping businesses reap these benefits through our comprehensive and user-friendly preventive maintenance asset management software.

Developing a Preventive Maintenance Plan

Implementing a preventive maintenance strategy takes time to happen. It requires careful planning and a systematic approach. This section will walk you through the steps to develop a comprehensive preventive maintenance plan for your organization.

Evaluating Needs and Priorities

Understanding your end goals is the first step in creating a preventive maintenance plan. These could include reducing downtime, lowering repair costs, improving inventory management, or increasing production rates. Identifying these goals will help you prioritize your assets and decide which ones require the most attention.

To simplify this process, you can group your assets into categories such as location, priority, or family. This way, your maintenance team can quickly identify the critical assets that require immediate attention.

Considering the Financial Impact

Preventive maintenance requires a financial commitment. However, it's essential to understand that the cost of preventive maintenance is often offset by the savings from avoiding unplanned downtime and costly repairs. According to research from Aberdeen, unplanned downtime can cost businesses an average of $260,000 per hour.

Therefore, considering the financial impact of implementing a preventive maintenance plan, consider the long-term savings and benefits, not just the upfront costs.

Using Data to Make Informed Decisions

Data is the cornerstone of an effective preventive maintenance plan. By leveraging historical data, you can predict when an asset will likely fail, enabling you to schedule maintenance activities just in time.

Moreover, by charting equipment maintenance history, you can keep your assets in optimal condition and avoid overusing equipment past its useful life. This ensures peak performance and minimizes the risk of safety hazards and suboptimal output.

The Role of Asset Management Software in Developing a Preventive Maintenance Plan

A Computerized Maintenance Management System (CMMS) is critical to automating and optimizing your preventive maintenance plan. A CMMS like the one we offer at MicroMain allows you to schedule maintenance tasks, prioritize work orders, automate work orders, and attach critical documentation to digital asset files.

Furthermore, our CMMS can be utilized to establish plans and reports that trend asset performance and aid in decision-making. This valuable information lets you decide when and how to maintain equipment.

In summary, developing a preventive maintenance plan is a strategic process that involves evaluating your needs and priorities, considering the financial impact, using data to make informed decisions, and leveraging the power of asset management software. At MicroMain, we're here to help you navigate this process and implement a preventive maintenance plan that optimizes your operations and maximizes your ROI.

At MicroMain, we understand the value of such a comprehensive and integrated approach to preventive maintenance. We offer a range of solutions, including our Preventive Maintenance Software, designed to help businesses streamline their maintenance operations, reduce costs, and optimize asset performance.

Our software has powerful features such as asset management, work order tracking, inventory control, labor management, and predictive maintenance. We are committed to delivering industry-leading solutions that support your preventive maintenance asset management strategies and drive your business success.

Conclusion: The Future of Preventive Maintenance Asset Management

As we've seen throughout this guide, preventing maintenance asset management is continuously evolving—the future points towards a more automated, data-driven, and predictive approach to maintenance. Advanced technologies like IoT, AI, and machine learning are becoming increasingly integral in guiding maintenance strategies, fostering a shift from reactive to preventive and even predictive maintenance.

Businesses are realizing the immense potential of harnessing real-time and historical data to optimize maintenance processes and extend the lifespan of their assets. As discussed, using CMMS and EAM systems has become vital in streamlining preventive maintenance tasks, providing increased transparency, improved resource allocation, and reduced operational downtime.

At MicroMain, we understand the need for dynamic, reliable, and user-friendly software to manage your preventive maintenance strategies. The key to successful implementation lies in choosing a system that integrates with your existing technological infrastructure and is intuitive and user-friendly. That's why we've developed our CMMS and EAM solutions to provide the tools you need to optimize your maintenance operations.

In conclusion, effective preventive maintenance asset management is no longer a luxury but a necessity for businesses. It's about more than just maintaining equipment - it's a strategic approach that directly impacts your bottom line. As we move towards a future where efficiency and reliability are paramount, preventive maintenance will continue to play a critical role in asset management.

As your trusted partner, we at MicroMain are committed to supporting you on this journey, providing industry-leading solutions that meet your needs and drive your success. We invite you to learn more about our preventive maintenance software and how it can help enhance your maintenance operations.

Embrace the future of preventive maintenance asset management with MicroMain. Together, we can ensure the optimal performance and longevity of your assets, contributing to your business's overall success and efficiency.

For additional insights into PM maintenance and related topics, we invite you to check out these other articles on our site: -

Maintenance Management Resources - The Role of CMMS in Maintenance - The Future of Maintenance: Predictive Maintenance.

For immediate assistance, please call us at (512) 328-3235

For immediate assistance, please call us at (512) 328-3235