Do you need help with high maintenance costs, unplanned downtime, inefficient inventory management, or lack of reporting capabilities in your industrial manufacturing company? It's not uncommon. With equipment and machinery's increasing scale and complexity, traditional techniques need help managing maintenance operations effectively. That's where the concept of optimizing maintenance operations with software comes into play, and it can bring a paradigm shift in your organization's maintenance endeavors.

Brief Overview of Maintenance Operations

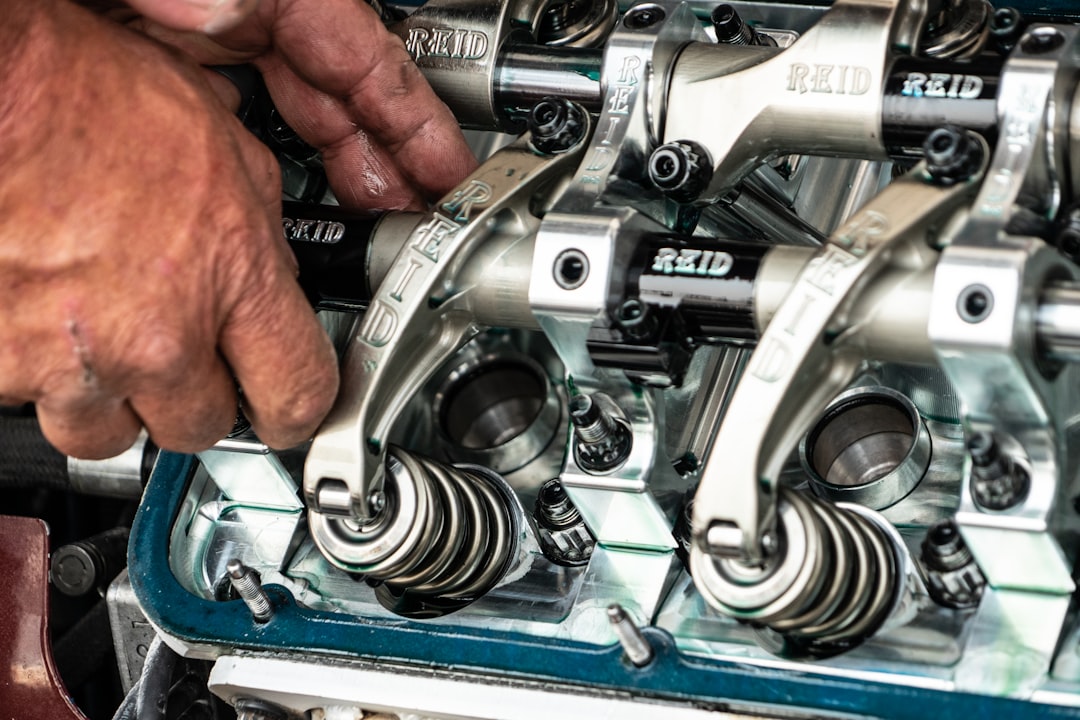

Maintenance operations typically encompass all activities required to keep a facility's assets (equipment, machines, buildings, etc.) in good operating condition. This includes many tasks: inspection, preventive maintenance, corrective maintenance, replacement, and repair. As critical as they are, these operations can become a significant source of expenditure and inefficiency if not managed effectively.

Importance of Optimizing Maintenance Operations

Optimizing maintenance operations minimizes downtime, increases asset reliability, reduces operational costs, and enhances overall productivity. It's all about finding the right balance; over-maintaining assets can be as detrimental as under-maintaining them. Hence, optimizing these activities requires a strategic approach where maintenance decisions are data-driven, prioritized tasks, and resources are efficiently utilized. Maintenance schedules are optimized based on asset condition and performance data.

Role of CMMS and EAM Software in Maintenance Operations

In an era of digital transformation, CMMS (Computerized Maintenance Management System) and EAM (Enterprise Asset Management) software have emerged as powerful tools to revolutionize maintenance operations. These software solutions automate and streamline maintenance tasks, provide valuable insights through analytics, enable efficient inventory management, reduce downtime, and ultimately improve the return on assets.

Key Your Quick Guide to Optimizing Maintenance Operations with CMMS and EAM software:

- Streamline and automate maintenance tasks

- Leverage data analytics for informed decision-making

- Plan preventive maintenance strategically

- Track all assets and manage inventory efficiently

- Use IoT technology for real-time equipment monitoring and predictive maintenance

- Ensure an ongoing process of feedback and continuous improvement

Understanding the Four Types of Maintenance Strategies

To understand how to optimize maintenance operations with software, it's crucial first to understand the four main types of maintenance strategies. These strategies include corrective, preventive, risk-based, and condition-based maintenance.

Corrective Maintenance

Corrective maintenance is a reactive approach that involves fixing problems as they arise. This strategy is often used when an asset fails or a fault is identified during routine operation or inspection. Technicians need access to the necessary information for corrective tasks, including problem description and asset history. A successful corrective maintenance strategy ensures equipment flaws are caught before they devolve into equipment failure.

However, relying solely on corrective maintenance can lead to unplanned downtime and higher long-term costs. At MicroMain, we advocate for a balanced approach that includes elements of both reactive and proactive maintenance strategies.

Preventive Maintenance

Preventive maintenance is a proactive strategy that involves regularly scheduled maintenance to prevent equipment failure. This type of maintenance can keep existing equipment in good working condition, prevent equipment downtime, increase asset lifespan, and help control maintenance costs in the long run.

Our preventive maintenance software helps maintenance supervisors plan labor and resources before the task is due. This ensures that parts are replaced only when necessary, reducing the risk of safety incidents caused by ill-maintained machinery.

Risk-based Maintenance

Risk-based maintenance aligns maintenance resources based on the criticality of the equipment. This strategy focuses on identifying and addressing maintenance issues that pose the highest risk to operations. Organizations can optimize maintenance schedules and resource allocation by implementing risk-based maintenance, ensuring that high-priority assets receive attention.

Our CMMS software enables organizations to implement risk-based strategies by providing tools for equipment criticality assessment, resource scheduling, and task prioritization.

Condition-based Maintenance

Condition-based maintenance is another proactive strategy that uses real-time data to monitor the condition of equipment and perform maintenance when certain conditions are met. This strategy uses meter readings and sensor alerts to indicate when maintenance is required.

At MicroMain, our software enables organizations to implement condition-based maintenance strategies, using sensor data and equipment monitoring to detect early signs of potential failures. You can maximize uptime and minimize costs by scheduling maintenance activities based on equipment conditions.

In conclusion, understanding and implementing these four maintenance strategies is crucial for any organization aiming to optimize its operations. Combining these strategies with powerful CMMS and EAM software can help you streamline processes, reduce downtime, and increase equipment lifespan.

The Role of CMMS in Optimizing Maintenance Operations

Following an understanding of the four main types of maintenance strategies, let's explore the role of Computerized Maintenance Management System (CMMS) software in optimizing maintenance operations.

Understanding CMMS and Its Features

A CMMS is a software solution designed to streamline maintenance management processes. It is a centralized platform that automates and simplifies tasks like work order management, preventive maintenance planning, asset and inventory management, and equipment tracking.

In addition to these core functions, our CMMS software at MicroMain offers advanced features such as safety instructions generation, risk assessments, and seamless integration with existing systems, all designed to improve efficiency and performance.

Benefits of Using CMMS in Maintenance Operations

CMMS software plays a crucial role in improving maintenance operations. It enhances efficiency by optimizing schedules, reducing downtime, and increasing equipment reliability. Businesses can leverage the data-driven insights of maintenance analytics for informed decision-making and predictive maintenance strategies to prevent equipment failures.

At MicroMain, we've seen firsthand how our CMMS software can provide an instant view of all maintenance operations at any given time, reduce the amount of work needed in periodic audits, and, ultimately, help companies reduce their maintenance costs.

Potential Challenges and How to Overcome Them

At MicroMain, we've seen firsthand how our CMMS software can provide an instant view of all maintenance operations at any given time, reduce the amount of work needed in periodic audits, and, ultimately, help companies reduce their maintenance costs.

Case Study: MicroMain's CMMS Software

Our CMMS software has been successfully used worldwide, helping organizations manage their maintenance operations more effectively. We have myriad customer stories demonstrating the transformative benefits of our CMMS software. You can check out our case studies page for an in-depth look at how our CMMS software has helped businesses optimize their maintenance operations.

In conclusion, integrating a CMMS into your maintenance operations can significantly enhance efficiency, reduce costs, and improve asset management. At MicroMain, we strive to provide robust, flexible, and user-friendly CMMS solutions designed to help you navigate the complexities of maintenance management and unlock new levels of operational efficiency.

The Role of EAM in Optimizing Maintenance Operations

In optimizing maintenance operations with software, the importance of Enterprise Asset Management (EAM) software cannot be overstated. EAM is a comprehensive solution that goes beyond the scope of traditional CMMS to manage the entire asset lifecycle, from design and procurement to operation and disposal.

Understanding EAM and Its Features

EAM software is more than just a maintenance tool. It is a strategic solution designed to manage and optimize the performance of physical assets throughout their lifecycle, encompassing everything from maintenance and inspection to replacement and disposal.

MicroMain's EAM software offers several robust features that enhance asset management, including preventive and predictive maintenance, multi-location management, asset lifecycle management, analytics, inventory management, labor tracking and management, and cloud-based operation. With these features, organizations can gain a holistic view of their assets, streamline maintenance operations, and make data-driven decisions for optimal asset performance.

Benefits of Using EAM in Maintenance Operations

Implementing EAM software can deliver multiple benefits. These include improved safety, reduced downtime, increased asset reliability, and enhanced customer satisfaction. Furthermore, EAM software can facilitate space management, more intelligent energy expenditure, and foster stronger working relationships within your organization. It's like having a birds-eye view of your assets, allowing for more informed decision-making and strategic planning.

Potential Challenges and How to Overcome Them

Despite its numerous benefits, adopting EAM software may pose challenges, including resistance to change, data accuracy, and ensuring stakeholder engagement. However, these challenges can be overcome with effective communication, training, and continuous improvement. It's also critical to prioritize security and ensure the software integrates seamlessly with your current systems.

Case Study: MicroMain's EAM Software

At MicroMain, our customers have experienced firsthand the transformative impact of our EAM software on their maintenance operations. For instance, our EAM software has helped organizations streamline and optimize their maintenance costs and processes across multiple locations, keeping track of asset performance, labor, inventory, and other data for each site.

In conclusion, optimizing maintenance operations with software such as EAM can be a game-changer for any organization. By leveraging the power of EAM software, organizations can enhance their asset management, improve efficiency, and ultimately achieve better maintenance outcomes. Discover how MicroMain's EAM software can transform your maintenance operations today.

How to Improve System Maintenance with Automation Tools

In the quest for optimizing maintenance operations with software, one crucial element is using automation tools. Automation plays a significant role in enhancing the efficiency and effectiveness of maintenance management. It can streamline processes, reduce errors, and free up time for higher-level tasks that require human judgment and expertise.

Importance of Automation in Maintenance Operations

Automation is vital in maintenance operations for several reasons. Firstly, it helps to reduce the time spent on routine, repetitive tasks. By automating these tasks, maintenance personnel can focus on more challenging and critical aspects of their job. Furthermore, automation minimizes the risk of human error, leading to more accurate and reliable results. Also, it facilitates real-time monitoring and reporting, allowing for quick detection and resolution of issues.

Types of Automation Tools for Maintenance Operations

Various automation tools are available for maintenance operations, each with different features and functionalities.

- Patch Management Tools: Automatically update systems with the latest patches, ensuring they remain secure and function optimally.

- Backup and Recovery Tools: These automate the process of backing up data and restoring it in case of loss or corruption.

- Configuration Management Tools: These help automatically manage system configurations, maintaining consistency and reducing errors.

- Monitoring Tools: These track system performance and alert administrators about potential issues before they escalate.

- Reporting Tools: These generate automated reports on various maintenance metrics, providing valuable insights for decision-making.

At MicroMain, our CMMS software provides a comprehensive suite of automation tools that streamline and optimize maintenance operations.

How to Implement Automation in Maintenance Operations

Implementing automation in maintenance operations involves several steps.

- Assess Your Needs: Identify the tasks that require automation based on their repetitiveness, complexity, and impact on operations.

- Choose the Right Tools: Review various automation tools and choose the best fit your needs and budget. At MicroMain, we offer a range of CMMS software that can be tailored to your specific requirements.

- Train Your Staff: Ensure your maintenance personnel are adequately trained to use the automation tools. This will maximize their benefits and minimize disruption to operations.

- Monitor and Refine: Once the tools are implemented, monitor their performance and make necessary adjustments to optimize their effectiveness.

By effectively integrating automation tools, you can significantly improve your system maintenance and take a giant leap forward in optimizing maintenance operations with software.

Techniques for Software Maintenance

For any business that uses software in its operations, maintenance is a crucial aspect that can't be ignored. Software maintenance involves modifying and updating software applications after delivery to correct faults and improve performance. You need to be aware of four types of software maintenance to maintain and enhance your software operations.

Corrective Software Maintenance

Corrective software maintenance involves the correction of discovered problems. These problems could be design errors, logic errors, or coding errors. Corrective software maintenance is reactive, occurring after a problem has been discovered. It is critical in reducing system downtime and improving user experience. At MicroMain, our CMMS Software helps track and manage these software issues, ensuring that corrective tasks are assigned and completed on time.

Adaptive Software Maintenance

Adaptive software maintenance refers to making changes to the software to keep it usable in a changing environment. This could be changes in the operating system, hardware, or any other external components on which the software depends. The goal is to ensure the software remains practical and functional in these changes. Our CMMS Software can help manage these changes, ensuring your system remains up-to-date and efficient.

Perfective Software Maintenance

Perfective maintenance involves making functional enhancements to the software to improve its performance and maintainability. This could be improving the user interface, optimizing codes, or adding new features. The goal is to make the software more efficient, reliable, and responsive to user needs. Our Preventive Maintenance Software can help manage these enhancements, ensuring that your software continues to meet the evolving needs of your business.

Preventive Software Maintenance

Preventive software maintenance involves activities aimed at preventing future problems. This could mean restructuring the code to make it more understandable, writing documentation to help with future maintenance, or updating the software to newer versions to avoid the problems of older versions. The goal is to reduce future system errors and improve the longevity of the software. Our Preventive Maintenance Software can help manage these activities, ensuring your software remains reliable and effective.

In conclusion, understanding these maintenance techniques and implementing the right strategies with the help of a CMMS or EAM software is crucial in learning how to optimize maintenance operations with software. By doing so, you can ensure reliable software performance, reduce system downtime, and improve overall operational efficiency.

Conclusion

Recap of the Importance of CMMS and EAM in Maintenance Operations

In this guide, we've explored the pivotal role of Computerized Maintenance Management System (CMMS) and Enterprise Asset Management (EAM) software in optimizing maintenance operations. CMMS helps streamline maintenance processes, improve asset management, and enhance efficiency with work order management and preventive maintenance planning features. On the other hand, EAM provides a robust tool for maximizing the useful life of assets, with critical features like asset tracking, centralized information, reporting metrics, and maximizing return on assets.

Both systems are instrumental in reducing downtime, improving productivity, enhancing equipment reliability, and providing data-driven insights for decision-making. Integrating these systems with emerging technologies such as IoT, AI, and ML further enhances their capabilities, paving the way for predictive maintenance strategies and more efficient maintenance practices.

Final Thoughts on Optimizing Maintenance Operations with Software

Learning to optimize maintenance operations with software requires a comprehensive understanding of your organization's maintenance needs, carefully selecting the right software and practical implementation strategies. It's essential to involve stakeholders, address resistance to change, and provide proper training and support to successfully adopt CMMS and EAM software.

With the right approach, you can harness the power of CMMS and EAM software to transform your maintenance operations, increase efficiency, and achieve organizational goals. The success of your maintenance operations is directly linked to the reliability of your assets, and these software solutions provide the tools necessary to ensure optimal asset performance.

At MicroMain, we're committed to helping organizations like yours streamline their maintenance operations with our industry-leading CMMS and EAM software solutions. We invite you to explore our comprehensive services and see how we can help you optimize your maintenance processes.

For further reading, check out our maintenance planning and optimization resources.

For immediate assistance, please call us at (512) 328-3235

For immediate assistance, please call us at (512) 328-3235