Have you ever wondered what keeps the cogs of a manufacturing plant turning smoothly?

Maintaining a productive and efficient manufacturing operation is no small feat. Beyond the labor of skilled workers and the roar of machines, there's the unsung hero of the manufacturing pipeline – the Maintenance Scheduler. Delve into the maintenance scheduler job description, and you'll quickly see how pivotal their role is in orchestrating the symphony of operations.

Without maintenance schedulers, stages of production can grind to a halt in an inefficient disorder, much like an orchestra without a conductor. Failures could spiral, halting production and causing losses that could have been avoided. Imagine you've assembled a team for a crucial maintenance task only to realize you're short-staffed, a vital machinery part has failed, and no replacement is in sight. Nightmare, isn't it?

That's why, here at MicroMain, we understand the value of a proficient Maintenance Scheduler in managing the backbone of maintenance activities in a manufacturing environment.

At a glance, a Maintenance Scheduler's key responsibilities include:

- Planning and coordinating maintenance tasks and resources

- Ensuring the availability of necessary personnel, supplies, and equipment

- Regular and effective communication with various stakeholders

- And most importantly, anticipating and proactively solving potential problems

The role of a Maintenance Scheduler extends beyond just creating schedules. They are the true advocates of your maintenance department, bridging gaps and ensuring smooth operations in the short and long term. But worry not; we will further walk you through this intricate yet fascinating job description in this comprehensive guide.

Key Responsibilities of a Maintenance Scheduler

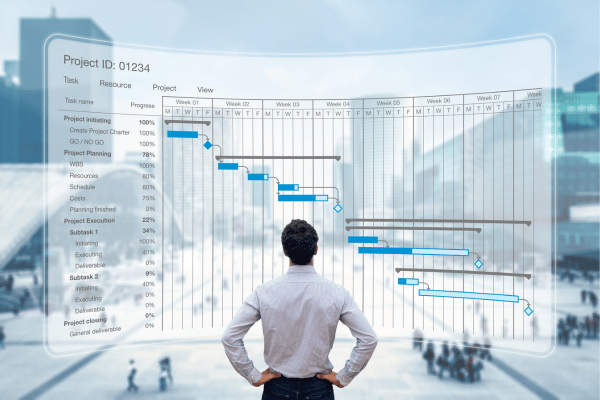

One of the primary responsibilities of a maintenance scheduler is planning, scheduling, and coordinating maintenance activities. This involves creating a detailed schedule of maintenance tasks that need to be performed, aligning these tasks with production requirements, and ensuring that they are carried out in an organized and timely manner. They are responsible for developing and executing an organization's maintenance plan and must also be adept at changing direction when emergencies arise.

In addition to scheduling tasks, maintenance schedulers also play a crucial role in ensuring the availability of necessary resources. This includes ensuring maintenance technicians have the tools and parts needed to complete their tasks. They're also responsible for effectively executing all maintenance work control processes, which involves bringing together all the resources necessary to complete a maintenance plan.

Communicating with various stakeholders is another key responsibility. Maintenance schedulers need to maintain open lines of communication with department personnel, suppliers, and contractors. They must be able to clearly and effectively communicate the schedule and any changes to it to everyone involved. This can include arranging meetings, conferences, and teleconferences and managing department calendars.

Lastly, a maintenance scheduler is tasked with proactively preventing potential problems. This involves working ahead to avoid the issues of supply that could disrupt the maintenance schedule. As one Reddit user put it, they should work proactively to prevent problems, and when things go wrong, they should work through the issues and get things back on track as quickly as possible.

These responsibilities highlight a maintenance scheduler's critical organizational roles, significantly minimizing equipment downtime and ensuring smooth production processes. The following section will explore the essential skills a successful maintenance scheduler should possess.

Essential Skills for a Successful Maintenance Scheduler

To fulfill the maintenance scheduler job description effectively, an individual needs a unique set of skills that enable them to manage complex tasks while ensuring the smooth running of the facility. These skills span from technical know-how to interpersonal abilities.

Proficiency in Computerized Technology

In the digital transformation era, proficiency in computerized technology is a non-negotiable skill for a maintenance scheduler. This involves understanding how to use maintenance management software like CMMS to streamline the scheduling process, track work orders, and manage resources effectively. This technology proficiency also aids in maintaining meticulous documentation of maintenance tasks and continuously updating information in the system.

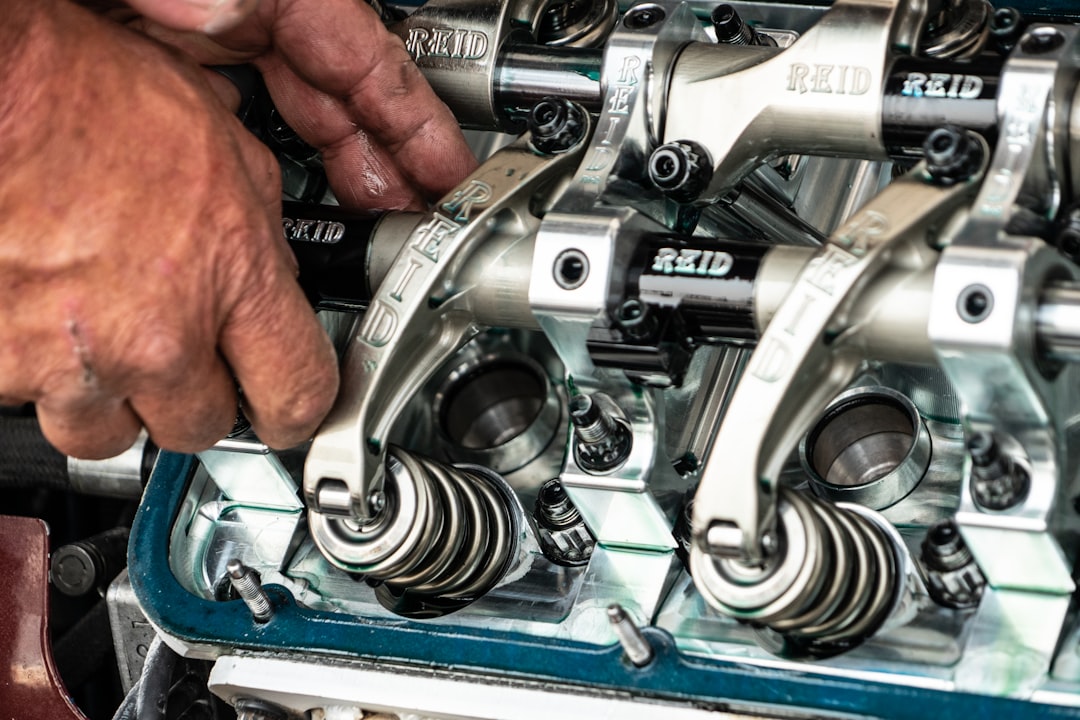

Technical Knowledge of Machinery and Equipment

A maintenance scheduler should possess a strong understanding of mechanical and engineering concepts. Even though they may not be required to perform maintenance tasks directly, they should understand the workings of the machinery and equipment at hand. This knowledge is vital in describing what needs to be done, estimating the labor hours, tools, and resources required to complete work orders, and aligning maintenance goals with core business requirements.

Time Management Skills

Time management is a crucial skill for a maintenance scheduler. They should be able to organize workflow and appointments, manage the department's schedule, and arrange meetings and conferences efficiently. A scheduler must prioritize tasks, especially during emergencies or a maintenance backlog. This ensures that maintenance activities interfere minimally with operations and production activities.

Effective Communication Skills

Strong verbal and written communication skills are essential for a maintenance scheduler. They are often required to write detailed work orders and manuals explaining complex processes, ensuring safety standards in the workplace. Good communication skills foster better coordination between different teams and stakeholders, making operations smoother.

Facility Management Skills

Lastly, a maintenance scheduler should be adept at facility management. This includes understanding the functional aspects of the facility, coordinating space utilization, and ensuring compliance with safety and operational standards.

In conclusion, the role of a maintenance scheduler is multifaceted, requiring a blend of technical and soft skills. The success of a maintenance scheduler largely depends on their ability to leverage these skills in managing and coordinating maintenance activities effectively. In the next section, stay tuned for a deeper look into the difference between a maintenance scheduler and a planner.

The Difference Between a Maintenance Scheduler and a Maintenance Planner

Understanding the distinction between a maintenance scheduler and a maintenance planner is essential when discussing the maintenance scheduler job description. Although the roles may sometimes intersect, they each have unique responsibilities and contribute differently to an organization's maintenance strategy.

Role of a Maintenance Planner

A maintenance planner is primarily involved in determining which maintenance tasks must be performed, how they should be completed, and what parts and tools are required. This role consists of developing maintenance strategies and coordinating the maintenance of all plant equipment. A good maintenance planner should have a strong understanding of mechanical and engineering concepts and be able to estimate the labor hours, tools, and resources needed to complete different work orders.

Role of a Maintenance Scheduler

On the other hand, a maintenance scheduler's role revolves around determining when to complete a task. They are responsible for organizing workflow and appointments, managing department schedules, and arranging meetings and conferences. A maintenance scheduler is also tasked with ensuring the availability of necessary resources for maintenance tasks. They must have a solid knowledge of computerized technology and be adept at facility management.

Why Both Roles Are Crucial in an Organization

The roles of the maintenance planner and the maintenance scheduler are crucial in an organization. They work together to ensure the seamless execution of maintenance plans, thus minimizing equipment downtime and ensuring smooth production processes.

A maintenance planner lays the groundwork for what needs to be done, while a maintenance scheduler determines when and how these tasks will be carried out. This synergy is vital for efficiently operating an organization's maintenance department.

At MicroMain, we understand the importance of these roles and how they contribute to the overall efficiency of an organization. Our CMMS and EAM software offer solutions that support both maintenance planners and schedulers, promoting effective communication, coordination, and proactive maintenance practices.

The Impact of a Maintenance Scheduler on an Organization

In an industrial or manufacturing setting, the role of a maintenance scheduler must be balanced. They are pivotal in ensuring the smooth operation of the organization. Their primary impact revolves around three key areas: minimizing equipment downtime, ensuring smooth production processes, and contributing to achieving production goals.

Minimizing Equipment Downtime

One of the primary purposes of a maintenance scheduler is to minimize equipment downtime. They do this by strategically scheduling maintenance tasks at times that have the most negligible impact on production. Scheduled maintenance tasks, which refer to regular inspections and repairs, are performed according to a well-defined schedule, ensuring that crucial machinery and equipment are always in optimal working condition. This proactive approach can avoid unexpected equipment breakdowns, leading to costly and disruptive downtime.

Ensuring Smooth Production Processes

A maintenance scheduler also plays a crucial role in ensuring smooth production processes. They coordinate resources, such as labor, parts, and materials, and effectively communicate maintenance schedules to relevant stakeholders. This ensures that maintenance tasks are performed efficiently without hindering the ongoing production activities.

Contributing to the Achievement of Production Goals

Moreover, a maintenance scheduler's job description contributes significantly to achieving production goals. Minimizing downtime and ensuring the smooth operation of production processes help the organization meet its production targets. The efficiency of scheduling maintenance tasks can also optimize the utilization of resources, leading to cost savings and improved productivity.

At MicroMain, we understand the crucial role that maintenance schedulers play in an organization. Our CMMS and EAM software are designed to support these roles, providing tools and features that streamline scheduling processes, enhance communication, and promote proactive maintenance practices.

How CMMS and EAM Software Support the Role of a Maintenance Scheduler

A maintenance scheduler is critical for ensuring smooth operations in complex maintenance management. However, maintaining the intricate balance of scheduling, coordinating, and managing resources can be challenging without the right tools. Enter Computerized Maintenance Management Software (CMMS) and Enterprise Asset Management (EAM) software. At MicroMain, we've designed our CMMS and EAM software to empower maintenance schedulers, optimize workflow, and boost efficiency.

Streamlining Maintenance Scheduling Processes

One of the key responsibilities in a maintenance scheduler job description is the efficient planning and scheduling of maintenance tasks. Our CMMS software is invaluable for generating maintenance schedules, creating work orders, and tracking task completion dates and labor times. It automatically maintains and updates the master schedule, providing a centralized portal to control and monitor work order assignments. This streamlined process aids in minimizing unscheduled downtime and maximizing technician productivity.

Enhancing Communication and Coordination

A maintenance scheduler must coordinate with various stakeholders and ensure clear communication. Our CMMS software supports this by providing a platform for real-time communication and collaboration. It allows for sharing work orders, maintenance schedules, and essential updates, ensuring all team members are on the same page. This reinforces the maintenance scheduler's role as a crucial link between the maintenance team and other departments.

Improving Proactive Maintenance Practices

Preventive and predictive maintenance are vital aspects of a maintenance scheduler's role. Our CMMS and EAM software promote these proactive maintenance practices by using past data to anticipate future maintenance needs. This prevents costly breakdowns and ensures equipment reliability. Furthermore, the software keeps track of warranty information, spare parts inventory, and regulatory compliance, thus equipping maintenance schedulers with all the necessary tools to manage their tasks effectively.

In conclusion, our CMMS and EAM software not only support the role of a maintenance scheduler but also enhance their productivity and efficiency. We believe in empowering maintenance schedulers with the right tools, making their job more accessible and practical. At MicroMain, we are committed to providing solutions that improve your maintenance operations and contribute to your organization's success.

Conclusion: The Integral Role of a Maintenance Scheduler in an Organization

A maintenance scheduler is pivotal in an organization, from ensuring the smooth running of daily operations to proactively preventing potential problems. Their tasks may often go unnoticed, but their contribution is significant. They form the backbone of any maintenance team, orchestrating tasks, resources, and personnel to ensure everything runs like a machine.

The maintenance scheduler job description involves coordinating maintenance activities, securing necessary resources, and communicating with various stakeholders. They also play a crucial role in minimizing equipment downtime and ensuring smooth production processes, contributing to achieving production goals.

Maintenance schedules often work hand in hand with maintenance planners. While their roles may seem similar, each has distinct responsibilities crucial to an organization's success. Maintenance schedules ensure that the resources are available and tasks are scheduled effectively, while maintenance planners focus on the bigger picture, designing the maintenance program and setting its goals.

The role of a maintenance scheduler can be demanding, but it can also be gratifying with the right tools. At MicroMain, we understand the challenges that maintenance schedulers face, so we have developed our CMMS and EAM software. These tools not only support the role of a maintenance scheduler but also enhance their productivity and efficiency.

Maintenance schedules are essential for any organization that relies on equipment and machinery. Their work ensures that operations run smoothly and potential problems are identified and resolved before they can cause significant downtime.

Investing in a maintenance scheduler's skills and tools can significantly benefit an organization. It's a role that requires a keen eye for detail, exceptional organizational skills, and a knack for problem-solving. But more than anything, it's a role that requires a deep understanding of maintenance processes and a commitment to keeping an organization's operations running smoothly.

To learn more about how MicroMain can support your maintenance scheduler and improve your maintenance operations, explore our maintenance management solutions or contact our team for more information.

.png?width=695&height=463&name=Im%20Pedro%20Fernandes%20(3).png)

In conclusion, the role of a maintenance scheduler is integral to an organization's success. Their meticulous planning and coordination ensure that resources are used effectively, tasks are completed on time, and operations run without a hitch. At MicroMain, we're proud to support these unsung heroes of the maintenance world with our industry-leading CMMS and EAM software.

For immediate assistance, please call us at (512) 328-3235

For immediate assistance, please call us at (512) 328-3235